By Terry Goodwin, Head of Operations, Kytun UK

When it comes to pitched roofs, facades, and rainwater systems, the headlines tend to go to the visible details – flashy finishes, sleek cladding and solar-ready builds.

But behind every well-performing roofline is a system of components working quietly, efficiently, and – if we’ve done our job right – entirely without drama.

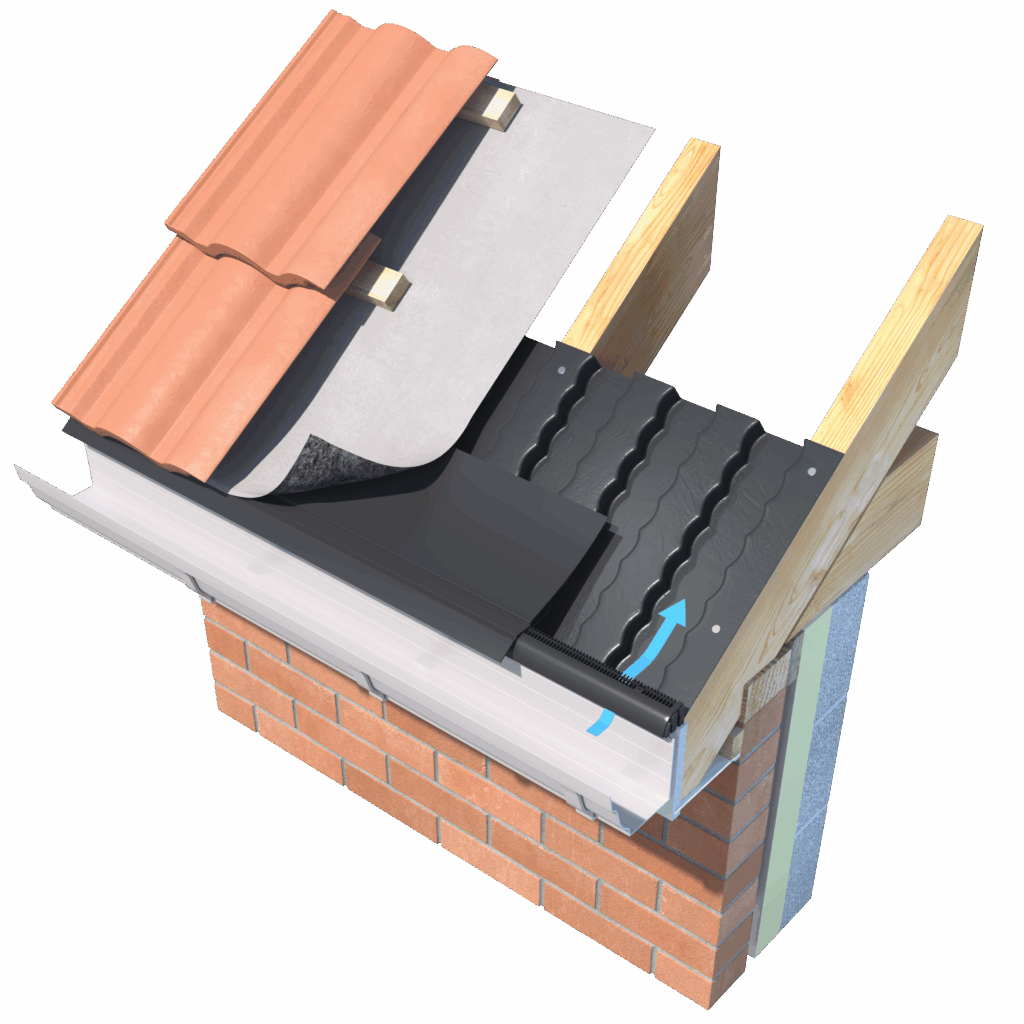

At Kytun, we manufacture high-performance plastic components that do exactly that. From dry verge to soffit vents, eaves systems to ridge kits, our products are engineered to withstand the toughest conditions – and built to last.

And they’re made from a material that rarely gets the credit it deserves: UV-stabilised, reprocessed PPC (Polypropylene Copolymer): a highly durable plastic derived from 100% recycled polymers. Unlike basic plastics, PPC offers superior strength, UV resistance and thermal stability – making it ideal for exposed roofline environments.

Why Plastics Matter in Performance Roofing

There’s plastic. And then there’s plastic engineered for roofing. Low-grade plastics can warp, fade, crack or fail. That’s why we never cut corners. All Kytun components are made from durable, ISO 9001:2015-certified materials and tested to the highest standards – impact strength, UV resistance, temperature stability, dimensional control.

No surprises. No shortcuts.

Our PPC-based products are made from recycled materials – and they can be recycled again. That’s not just sustainable. That’s circular, closed-loop performance.

In fact, every year we divert over 1,000 tonnes of plastic from landfill. And we’re not stopping there. Our R&D team is working on next-gen material derivatives to push performance even further.

From Factory Floor to Roofline. Built with Kytun Confidence

Every Kytun product follows a controlled, multi-stage manufacturing process in our state-of-the-art Donegal facility:

- Pellet testing and drying

- Precision moulding with robotic extraction

- Operator-led quality inspection

- Final batch testing and certification

This process ensures installers get the same result – every time. No warping. No callbacks. No second-guessing.

Because when you’re on site, consistency matters as much as quality. That’s why more and more installers are switching to Kytun dry fix systems: faster fitting, lower maintenance and longer life.

Supporting Roofers, Not Just Systems

We know the challenges roofers face. Our technical team works directly with merchants and installers across the UK and Ireland to deliver training, demos, and support.

Our message to the trade is simple:

If you want roofline plastics that are proven to perform – look to Kytun.

If you want peace of mind and long-term results – ask us why we build the way we do.

After 40 years in manufacturing, I’ve seen what happens when plastic components fail. And I’ve spent my career making sure ours don’t.

Sustainable Roofing Solutions

At Kytun, we are dedicated to advancing sustainability in every aspect of our operations.

Our PPC – Polypropylene Copolymer – range is proudly crafted from 100% recycled polymers, reinforcing our commitment to supporting a circular economy and significantly reducing plastic waste.

Our rigorous quality standards ensure that our roofing solutions deliver on both sustainability and performance.

Zero Waste Commitment

We take pride in our zero-waste philosophy. All production-related PPC scrap is either granulated and recycled within our factory or sent to external recycling partners for reuse – ensuring nothing goes to landfill.

By integrating these sustainable practices, we recycle an impressive 800 tonnes of PPC annually. It’s one more way we’re building a greener future and making responsible use of materials part of our everyday business.

And if you’re a builder or developer who needs to meet sustainability targets, choosing Kytun products does a lot of the work for you. Our recycled, recyclable, zero-waste components help you tick more of the right boxes – without compromising on performance.

Got Questions About Performance or Sustainability? Let’s Talk.

I’ve spent over 40 years in manufacturing and my favourite part of the job is still helping people understand what makes a good plastic product great. At Kytun, that means building roofline components that last, using recycled materials that work just as hard as you do.

If you’re a roofer, builder or developer who wants performance you can trust – and sustainability you can stand over – get in touch.

Terry Goodwin, Head of Operations, Kytun UK