Paul Manning, Managing Director at Manthorpe Building Products, looks at the challenges around roof space ventilation for roofing contractors, and gives an overview of the solutions Manthorpe offers to help roofers meet the latest requirements of BS 5250.

Manthorpe Building Products is a company that specialises in and understands the topic of ventilation particularly well. The company has been developing innovative building products for the construction industry for over 30 years and has extensive experience in the use of plastics, as well as the expertise to develop and manufacture virtually all its products in-house and continues to invest heavily in new technology and production processes.

All Manthorpe products are independently tested when required via independent testing organisations, such as Building Research Establishment (BRE) and Warringtonfire, to meet British Standards and to achieve relevant accreditations. The company prides itself on having close relationships with independent and national merchants, thus ensuring that its products are available from a wide range of outlets throughout the UK.

In 2021 BSI Standards published a major revision to BS 5250: Code of practice for Management of moisture in buildings. So, it is an opportune time to revisit the topic of ventilation.

Although the general approach to roof space ventilation and control of condensation has not changed markedly in this latest revision, it does contain new guidance on moisture risks other than condensation, a whole building approach to moisture-safe design, building context, the coherence of design and detailing interactions, as well as capacity and in-service conditions. It also covers the management of moisture risks in buildings undergoing energy saving measures.

The revision acknowledges key changes in modern building design, such as reduced air permeability of the building fabric and higher thermal insulation, both of which have the potential to increase the risk of condensation. It also considers changes in lifestyle and the greater use of moisture-generating appliances such as showers and internal clothes drying. Climate change is also predicted to add to the moisture risk through milder, more humid winters and more frequent and heavier incidents of driving rain events.

The differences between ‘as designed’, ‘as built’ and ‘in service’ conditions are now more clearly understood, as is the way occupants use the building, which may not always be in the manner intended, as well as the residual moisture held in the building fabric from the construction processes. This all means that the moisture risk evolves and changes over time and during the lifetime of the building, and designers are encouraged to allow for the worse-case scenario.

As well providing guidance developed through modelling, BS 5250 gives prescriptive guidance based on the evidence of many years of successful use. This particularly applies to roof construction, where there is plenty of data and evidence to provide practical recommendations for the use of ventilation to prevent moisture risk.

Whilst continuous eaves and dry ridge systems can generally be relied upon to provide the required ventilation into loft spaces for straightforward gabled roofs, sometimes the roof design means that extra ventilation is necessary. For example, where ridge, or high-level ventilation is required, but the ridge length is very short on a hipped roof, tile ventilators positioned in the hip end roof slopes are an ideal way to supplement the high-level ventilation of the roof space.

Manthorpe is one of the UK’s leading experts on roof space ventilation and offers some unique and innovative products to ensure compliance with BS 5250 and maintain a condensation-free roof structure.

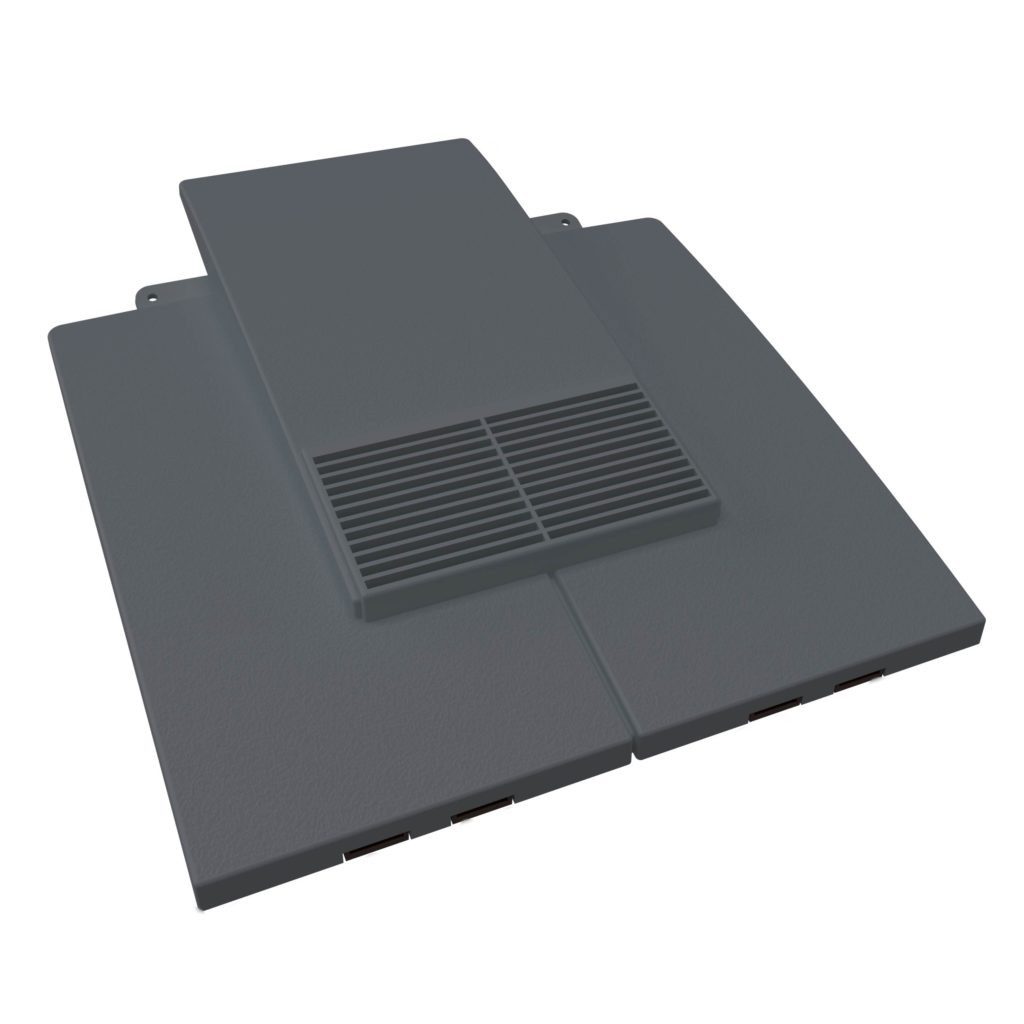

For example, the Cowled Universal Roof Vent, or CURV for short, is possibly the only truly universal tile ventilator on the market. It can be used with a wide variety of single lapped roof tiles and slates, making it especially useful where the installer may not know what the roof covering is. It can be used with large and small format interlocking tiles, both flat and profiled in design, including deep bold roll styles of tile and, with a minimum roof pitch of just 12.5 degrees, it is one of the lowest pitch ventilators on the market, making it ideal for lean-to house extensions. The vent is fitted with a versatile flashing skirt which can be dressed to match the relevant profile of the roof covering and comes with an adhesive mastic backing which securely seals the flashing down to the roof. The hooded cowl protects the opening from the elements whilst providing an airflow path into the roofspace. An integral 4mm louvred grill within the cowl prevents the entry of debris and large nesting insects. For mechanical extraction or soil stack / vent pipe termination, the lower outlet is stepped to allow for 4″, 5″ or an oval 6″ connection. The CURV has been fully independently wind-driven rain tested and is the perfect single-stock vent for merchants and roofers alike.

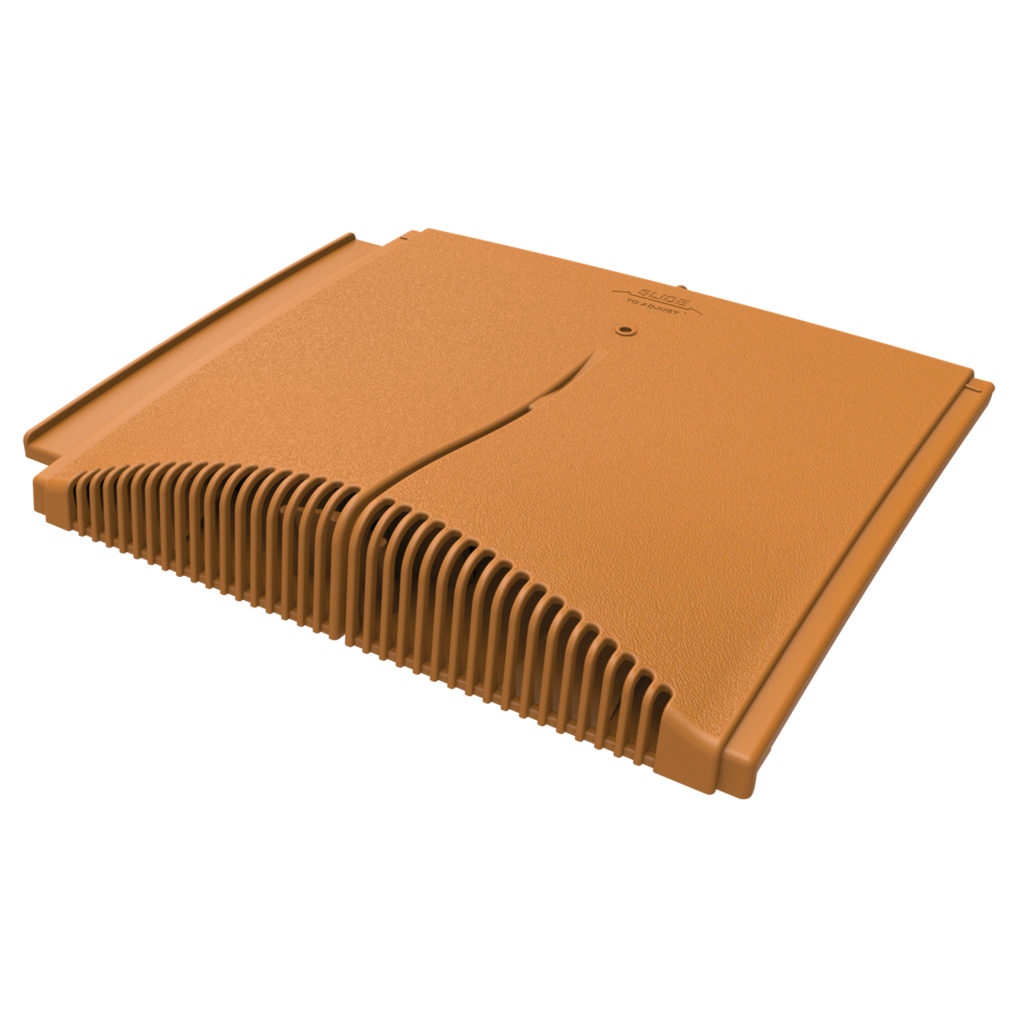

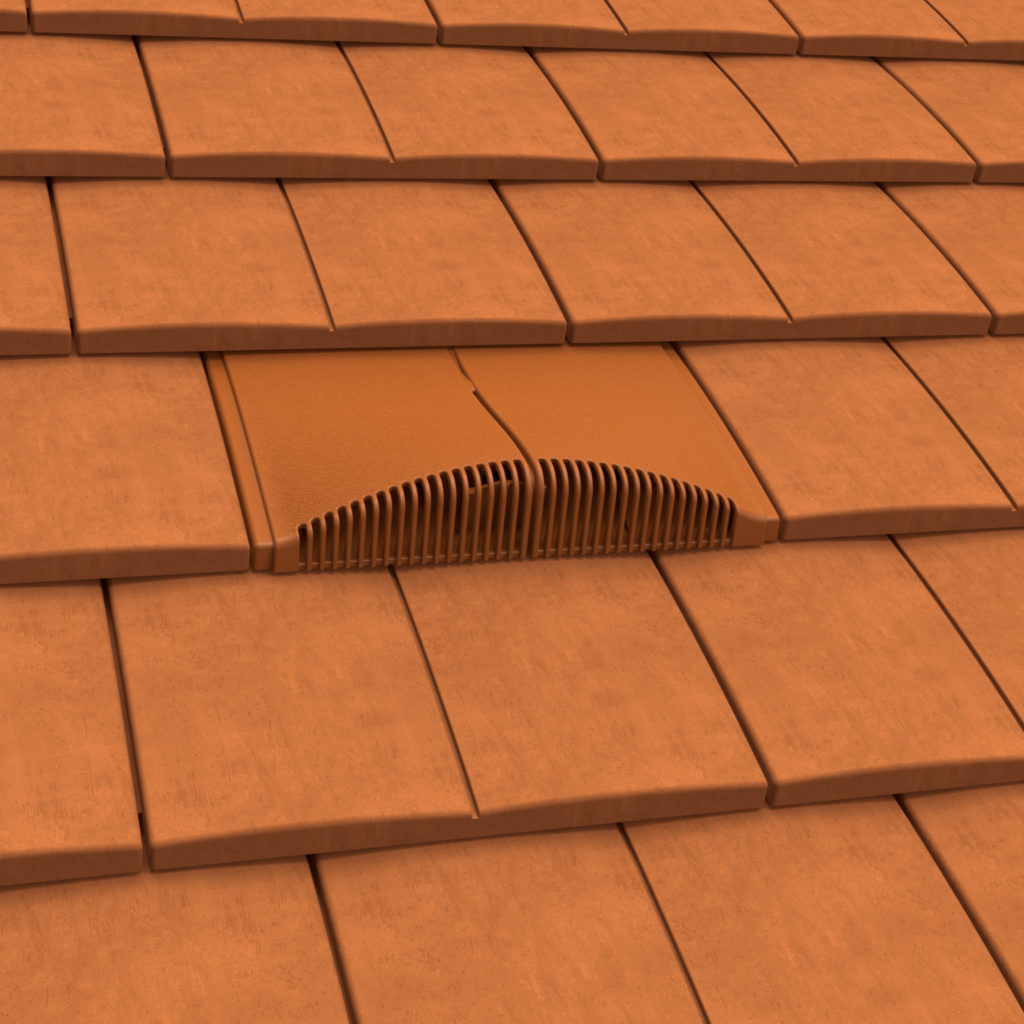

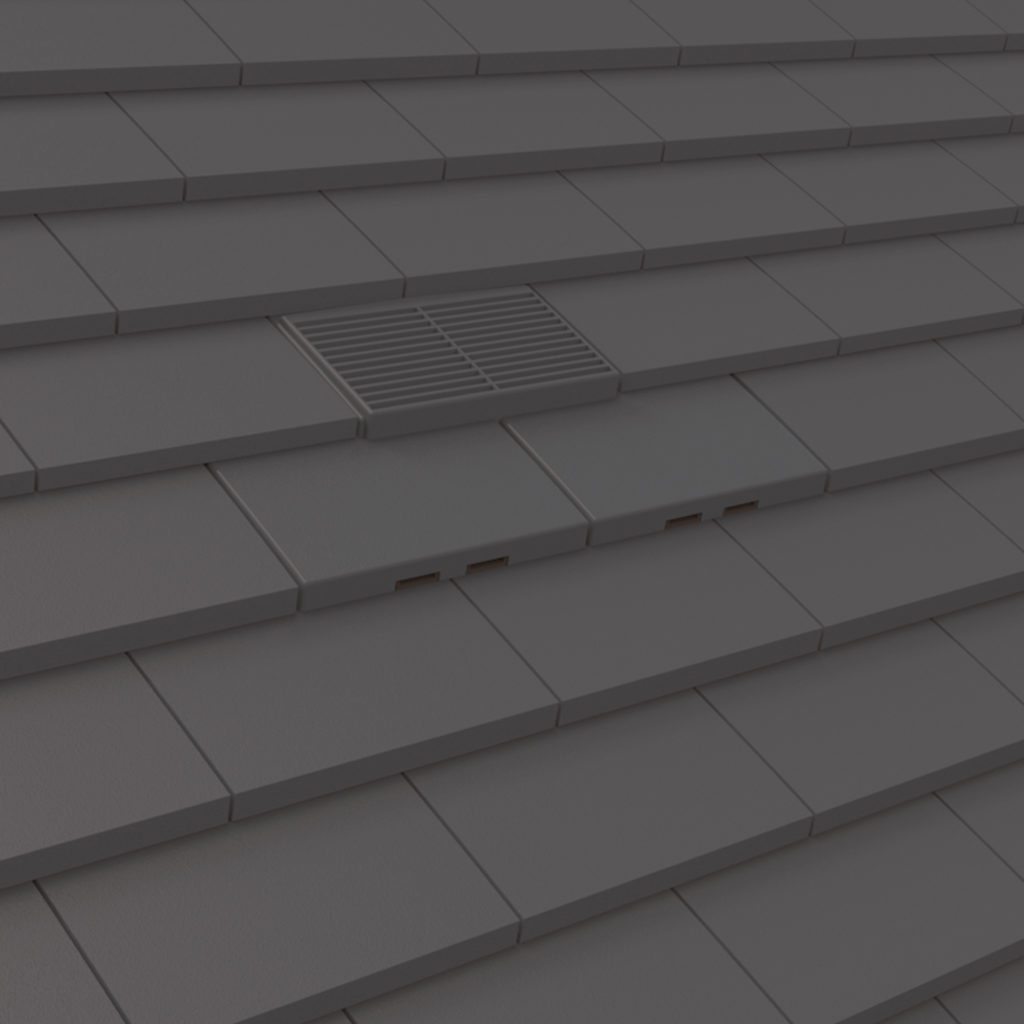

Another innovative product in the Manthorpe range is the interlocking plain tile ventilator, designed specifically for use with small format twin, or duo plain tiles. This product incorporates a unique patented design feature, a sliding mechanism, to adjust its width to suit the different sizes of tiles available. This means that it is the only vent which suits all the versions of concrete interlocking plain tiles currently on the market. This makes it ideal for merchants and contractors, who only need to stock one interlocking plain tile vent product.

The curved, in-line profile of the Manthorpe plain tile ventilator helps to maintain an unbroken appearance to the roofline at high or low level with a range of colours available to suit varying roof styles. The vent is suitable for roof pitches down to 22.5 degrees and is fully wind driven rain tested. The intricate path through the internal weathering geometry is designed to maintain a constant airflow gap of 6,000mm² whilst safely channelling any water out of the vent and on to the roof covering below. The 4mm louvred grill prevents the entry of debris and large nesting insects.

When using the vent for mechanical extraction or soil stack / vent pipe termination, a 4″ pipe adaptor can be fitted to the vent to connect to one of the GRPA Flexible Pipe range.

Both these innovative ventilators can be easily connected to one of the Manthorpe range of GRPA Flexible Pipes to continue the ducting further into the roofspace.

One of the great advantages of using products from a manufacturer such as Manthorpe, who are independent of the roof tile manufacturers, is that they can develop products that are compatible with the roof tiles of several manufacturers, reducing the need to stock many different ventilation systems.

Paul Manning

Managing Director, Manthorpe Building Products