The selection of roof tile underlay may be based on many considerations including ease of handling and forming the correct amount of drape, wind zone suitability and of course cost.

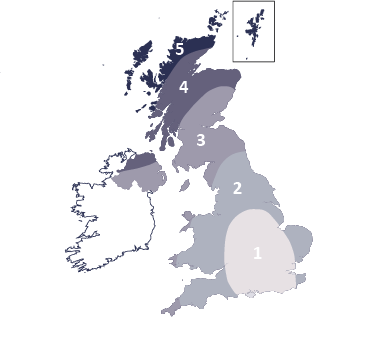

It is the wind zone suitability where there is still some misunderstanding and confusion as this is less straightforward than simply the geographical location.

Product Labelling

The key reference Standard for pitched roofing is BS 5534:2014+A2:2018 Slating and tiling for pitched roofs and vertical cladding. Code of practice. Section A.8 covers the zonal classification of underlays and includes an illustration of a zonal-classification label for a roofing underlay. This comprises of the wind uplift resistance values at different batten gauges and the wind zone suitability based on a limiting set of criteria such as the sealing level of the ceiling, ridge height, roof pitch, site altitude and site topography.

In some cases, the only information that is taken into account when selecting underlay is the geographical location in relation to the BRE (Digest 489) wind zone map. This, however, completely overlooks the limiting criteria which must be taken into account.

For example, Daventry – where Hambleside Danelaw is located – falls comfortably into wind zone 1 on the map. However, one of the limiting criteria of the BS 5534 labelling template is that site altitude should not exceed 100m. As Daventry sits above 100m metres above sea level, an underlay suitable only for zone 1 may not be suitable, and one that might be suitable for zone 3 or even zone 4 may be required.

Wind Uplift Resistance

For all new build work, the tile fixing specification should state the determined peak velocity wind pressure that should be used to determine the suitability of the underlay. Hambleside Danelaw’s LR180 for example, can be used in wind zones 1 to 4 and has a wind uplift resistance of 1378 Pa with tile battens spaced at 345mm and batten lap restraint. This value increases as the batten gauge reduces. Lighter weight underlay products with laps that are sealed with a tape can often exceed this level of wind uplift resistance, particularly when using an integral tape-to-tape system such as the Danelaw LR120TT option.

All of Hambleside Danelaw’s Low Resistance (LR) Underlays carry labels that declare the tested wind uplift resistance, independently verified by BRE, which can be compared to the peak wind uplift load as stated in the fixing specifications.

In some cases, such as re-roofing or roof alterations, there may be no wind load resistance figures available; it then becomes prudent to err on the side of caution and select a product that is more likely to exceed the wind uplift resistance required than one that is inadequate.

One of the methods that can be followed is by engaging an independent technical assessor or roofing underlay manufacturer, who will be able to advise on a more project specific basis.

Selecting the Right Product

Underlay roll labels should have the wind zone use shown clearly along with the wind uplift values for different batten gauges and any limiting criteria.

Underlays backed by third-party accreditation, such as BBA certification, provide reassurance of a consistency of product quality and fitness for purpose to suit the actual applications required.

Hambleside Danelaw’s range of LR roofing underlays are BBA certified demonstrating that manufacturing process is audited regularly to ensure consistency of quality and performance.

Find Out More

To learn more about Hambleside Danelaw’s range of LR underlays, please see https://www.hambleside-danelaw.co.uk/pitched-roofing/products/roofing-underlays/ or get in touch via our contact page, or email sales@hambleside-danelaw.co.uk.

Hambleside Danelaw also offer a RIBA accredited CPD course: Understanding the Function and Selection of Roof Tile Underlays, which can be booked online.