Alicia Garfoot, Products & Systems Design Technician at Wienerberger

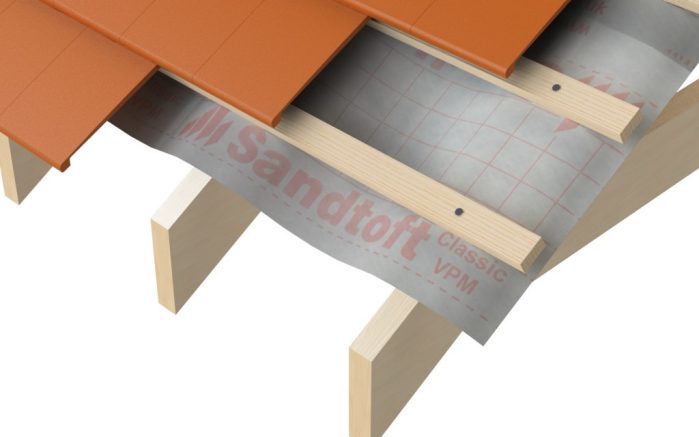

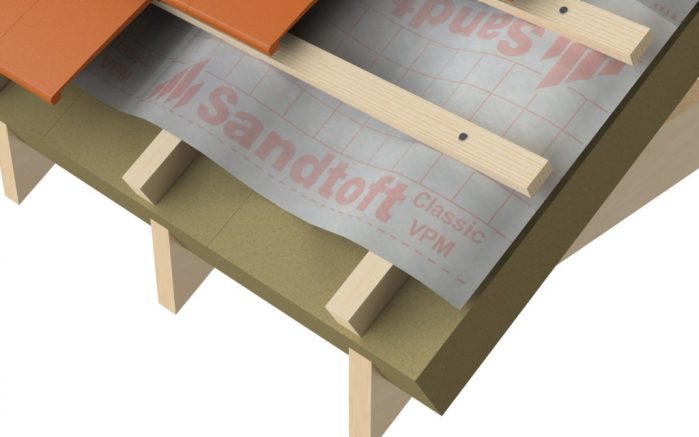

Underlay, felt, membranes. Whichever term you prefer to use, they are a key component when constructing any roof, offering a second protective barrier from the elements. All roof tiles can let some water through in extreme circumstances and therefore it is the job of the underlay and the sub roof, when detailed correctly, to deal with this water and disperse it into the guttering below.

Throughout the years there have been many forms of underlays on the market. Traditionally bitumen felt was the most common, however, the market has naturally progressed, and vapour permeable membranes are now the typical choice. Bitumen underlays still have their place, particularly in refurbishment work and specifically, for conservation requirements, bituminous 1F felt is recognised and utilised in projects where bats are present in the roof space, as they are seen to reduce bat entanglement. Commonly on heritage and conservation re-roof projects, but also any property where bats can be found, a 1F felt will be specified in order to protect and preserve the species.

The market moved away from bitumen underlays as the norm well over 20 years ago. Since then, manufacturers have developed a variety of vapour permeable membranes, leaving the roofing market spoilt for choice. It is easy to presume that all vapour permeable membranes are the same, just with different company branding, but this is not the case. They can and do all have different characteristics and requirements.

Choosing Your Underlay

The choice of underlay goes hand in hand with the choice of roof tile, alongside where the project is based in the country. All manufacturers should offer datasheets displaying zonal tables, highlighting where each of their underlays are suitable for use throughout the United Kingdom. In addition to this the gauge the roof tile is to be laid at should be taken into consideration, as the zones in which they are stated suitable for use will depend on the batten gauge of the tile above. Primarily because the wind uplift performance of each underlay is affected by the primary covering above.

Wienerberger offers three types of vapour permeable membrane, all designed in accordance with relevant British standards. There are membrane products available to compliment all Wienerberger roof tiles, across all locations within the UK. So, when making the decision of which to use, our recommendation is always to check with the manufacturer for guidance on suitability, installation and ventilation requirements.

Selecting the right roofing membrane can seem a difficult choice. One of the common misconceptions is that vapour permeable membranes provide enough ventilation alone to not require any further ancillary ventilation products. This is incorrect, membranes classed as vapour permeable are not classed as a ‘breathable’ membrane. As their name somewhat suggests, they only let vapours through, and this is not enough to minimise the risk of condensation problems which can be extremely costly to rectify down the line. Manufacturers supply varying ridge systems, tile ventilators, eaves ventilators, amongst other products to provide adequate roof space ventilation and we always recommend contacting the manufacturer to clarify exactly what is needed for your project.

Underlay Detailing

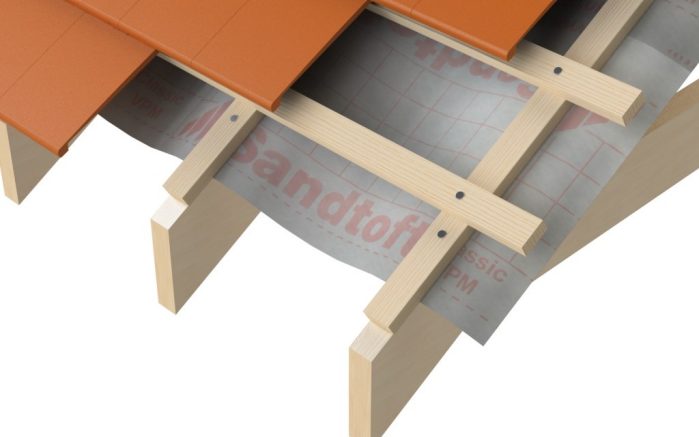

The detailing of underlays should also be mentioned. When using a vapour permeable membrane, ridge ventilation is often required to minimise the risk of condensation. We commonly see that the underlays are carried over the ridge when installed with a dry ridge system. However, the underlay should stop just short of the ridge allowing for an air gap. Without this, any air rising will not be able to escape and can ultimately lead to a condensation build up. Another common mistake is regarding drape. Bituminous felt, due to their weight, naturally created the required drape to allow any water to run underneath the battens and down to the eaves. However, when using a vapour permeable membrane, this drape has to be manually incorporated by the roofer to ensure correct detailing is achieved. Pulling the membrane tight often leads to rips and tears and more commonly, the pooling of water behind battens, leading to leaks into the property.

With all of that said, we are now seeing an increased number of air permeable membranes on the market, such as Protect’s Viking Air. Some of which, manufacturers will state require no additional ventilation products to be specified alongside. They are becoming increasingly popular and certainly have the potential to eventually become the industry norm instead of VPMs. Our recommendation, should you wish to use one of these products alongside a Wienerberger tile, would always be to contact the manufacturer of the specific underlay product for their guidance on ventilation.

As discussed, there are many factors to consider when specifying a suitable underlay for any project. We have seen transitions from bitumen felt to vapour permeable membranes, and possibly looking towards a future with the predominant use of air permeable membranes. Each product offers their own individual benefits and there is still a use case for each. Taking into consideration, location, roof build up, ventilation requirements, primary roof covering, associated ventilation accessories and ultimately following recommended guidance from manufacturers, will help highlight the most suitable product for any project.