The latest government initiatives aimed at reducing carbon emissions in buildings can have a direct and significant impact on the risk of condensation. For example, tighter building envelopes with enhanced insulation and airtightness are effective in reducing heat loss and energy consumption, but they can also trap moisture inside buildings. Also, the adoption of high-efficiency heating, ventilation, and air conditioning (HVAC) systems, whilst contributing to energy savings, may alter the temperature and humidity dynamics within buildings, especially if the system is poorly balanced or incorrectly maintained. This all means that good quality ventilation, not just of the living space, but also of the structure, is ever more important to ensure effective moisture control.

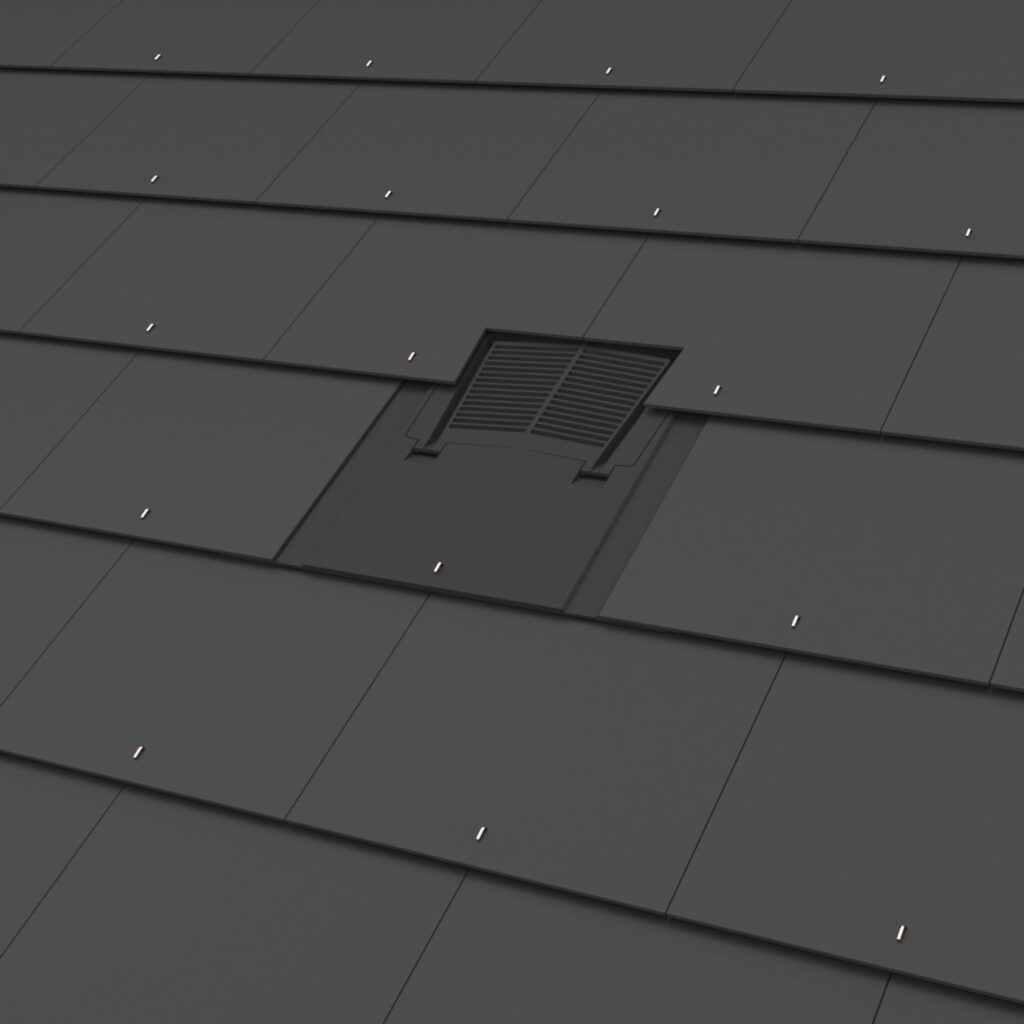

Manthorpe roof tile ventilators are a practical and efficient solution to addressing the ventilation needs in roof structures.

The Manthorpe In-line ventilator range includes:

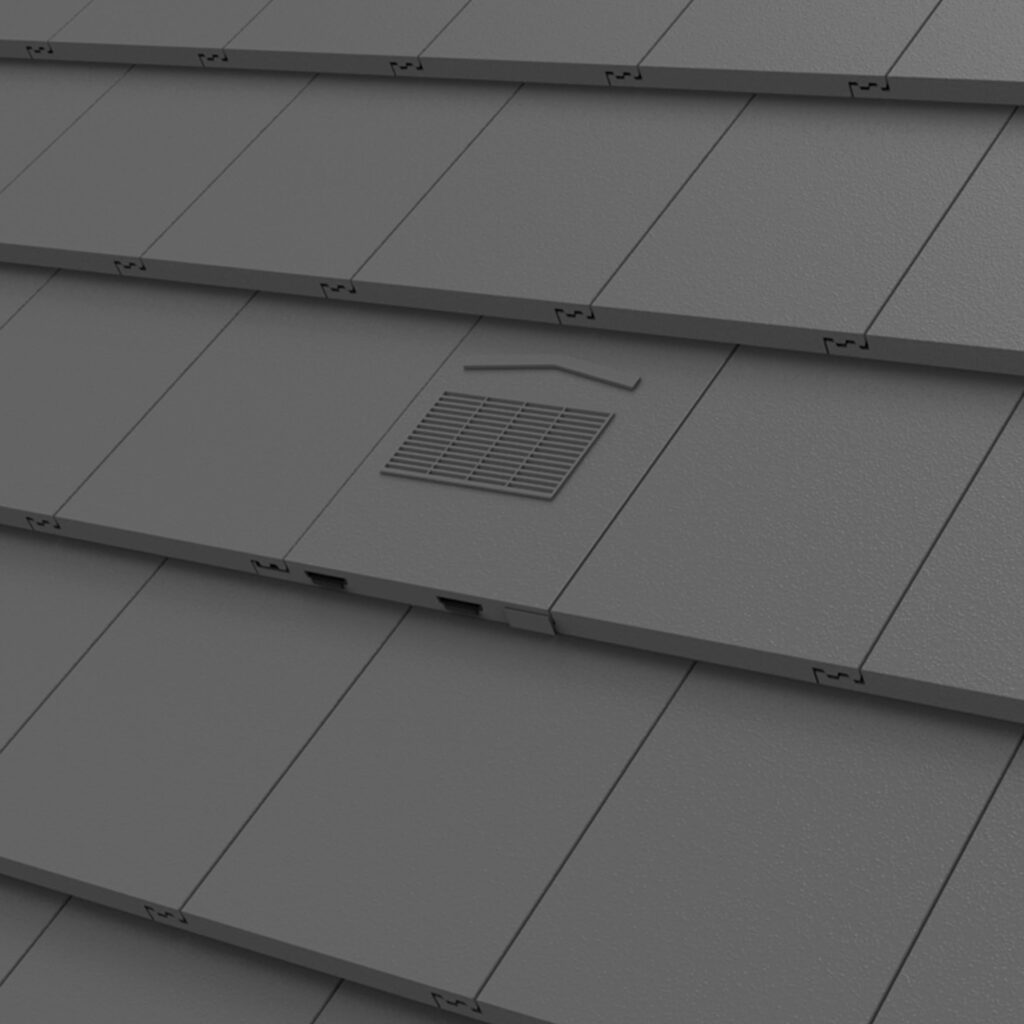

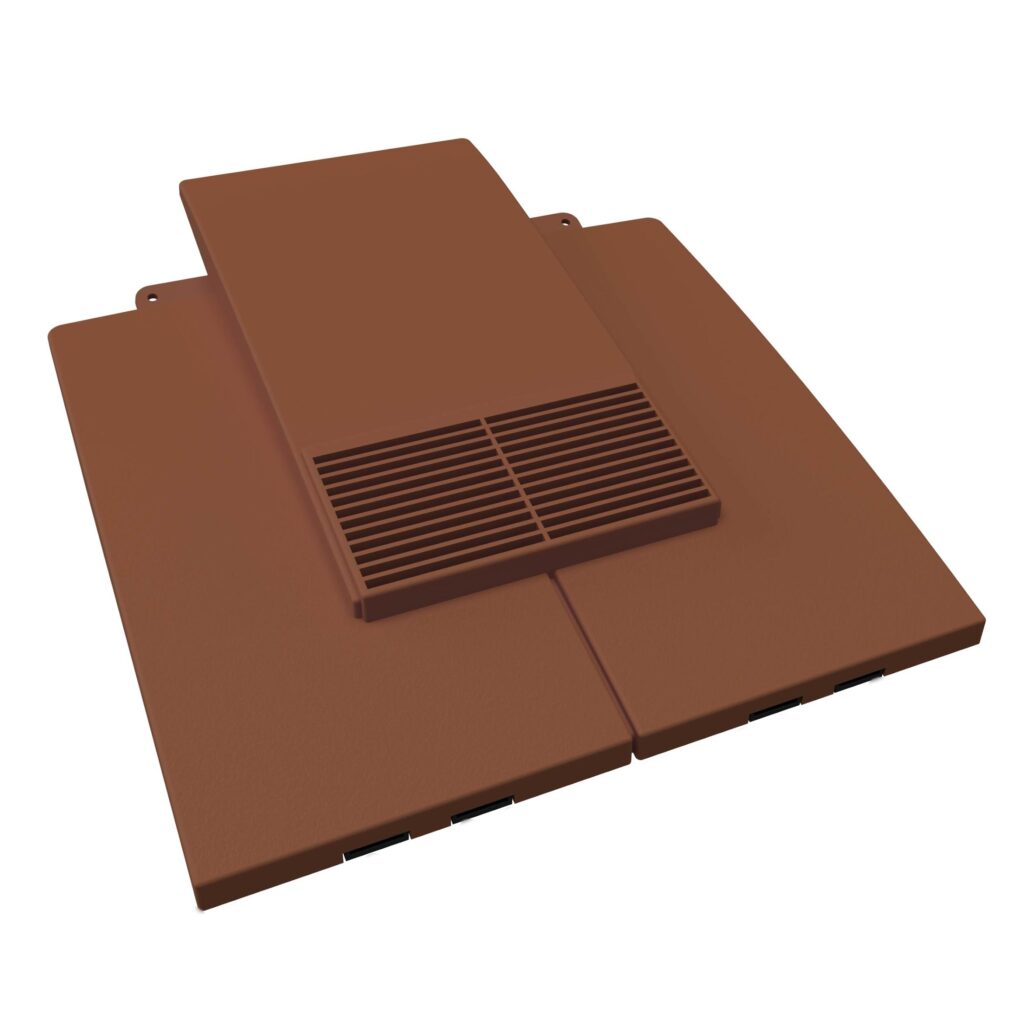

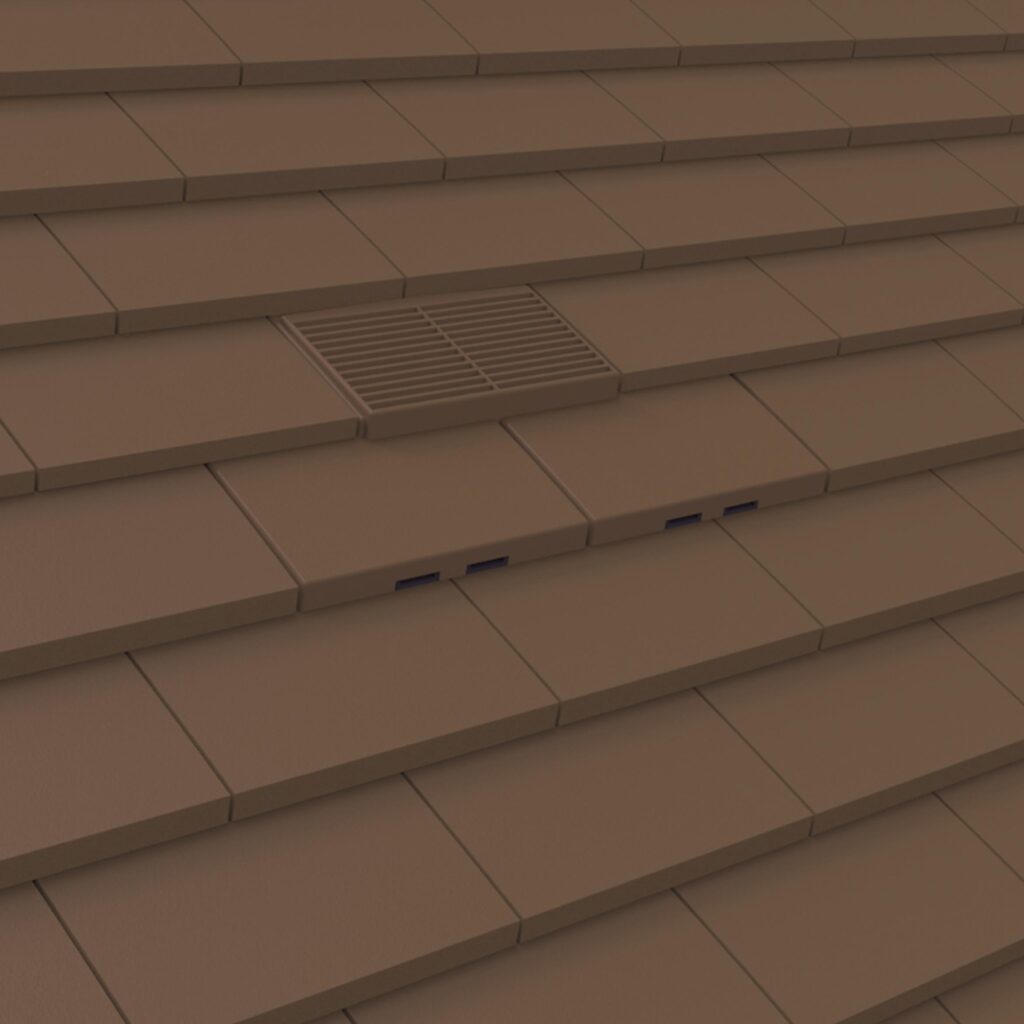

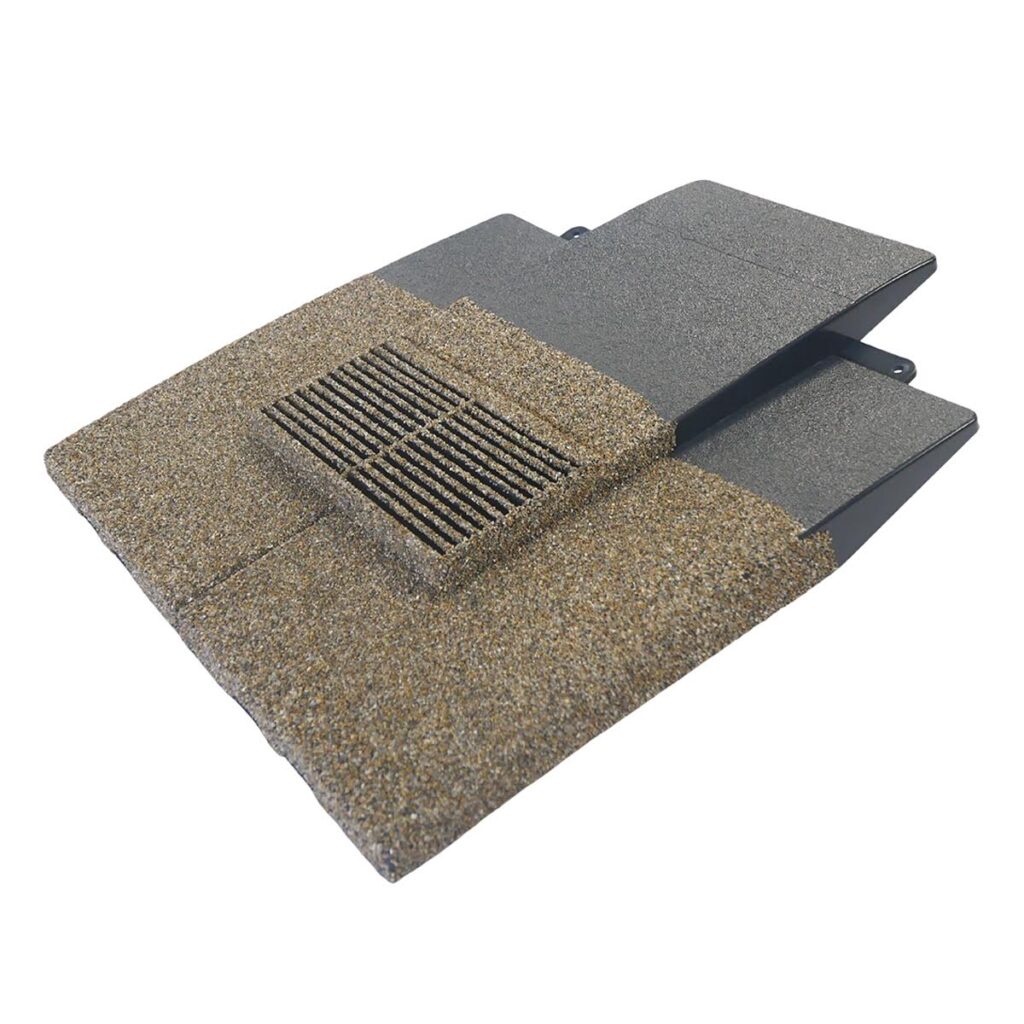

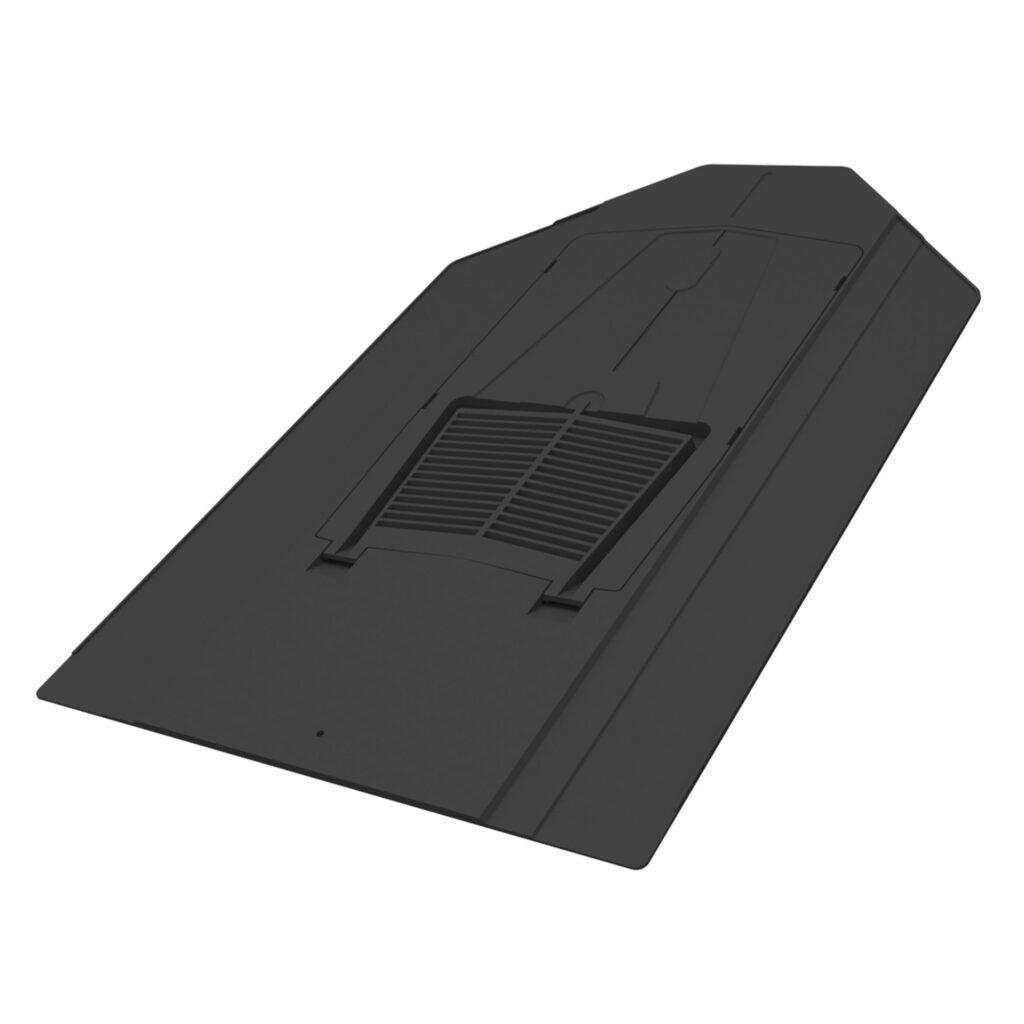

- Non-profiled tile ventilators to suit most large format flat interlocking tiles.

- Mid and large-format profile ventilators to suit most common manufacturer’s tile shapes, including the popular 15 x 9 castellated tiles and single concrete pantiles.

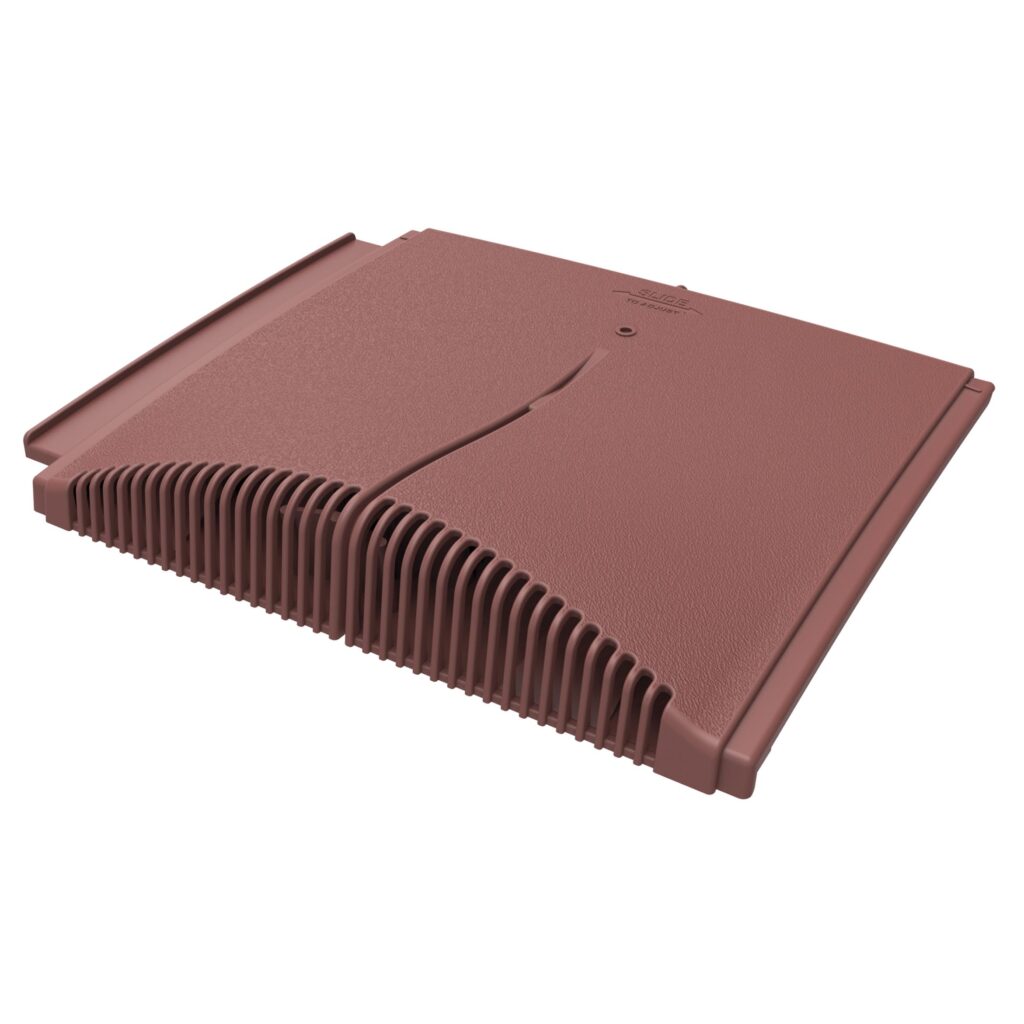

- An interlocking plain tile ventilator for use with small format twin plain tiles. This ventilator features a unique sliding mechanism to adjust its width to suit all three styles of interlocking plain tiles: Redland DuoPlain, Marley Ashmore and Forticrete Gemini.

- A plain tile ventilator to suit traditional double lapped plain tiles.

- A large format 600 x 300mm slate ventilator, which can also be used for 500 x 250mm slates by trimming the adjacent slates.

- A small format 500 x 250mm slate ventilator, which can also be used for slates down to 400 x 200mm by trimming the adjacent slates.

Manthorpe in-line ventilators are available in a wide range of colours, including textures to suit sand-faced tiles. They are easy to install and provide a quick and simple solution to roof space ventilation, mechanical extraction, and soil stack ventilation.

There are many roof tile and slate ventilators on the market, but not all are what they claim to be. A common example are ventilators where the supplier claims a free ventilation area of 10,000 square millimetres. Yet, they are supplied with an integral 100mm pipe adaptor. Everyone who remembers their school day mathematics will know that the area of a 100mm diameter circle is Πr2, which is approximately 3.142 x 502 = 7,855 square millimetres, thus reducing the effective free vent area of the ventilator. Installing ventilators which have a smaller free vent area than specified runs the risk of under-venting the roof space and consequently increases the risk of harmful condensation.

The entire range of Manthorpe roof tile and slate ventilators has been tested and certified by the British Research Establishment (BRE) for resistance to rain penetration in accordance with CEN Standard FprEN 15601. The test conditions represent typical worse-case conditions expected in Northern Europe during a 50-year return period. The testing showed the weathertightness performance of the ventilators to be better than that of the surrounding tiles.

BRE has also measured the aerodynamic characteristics of Manthorpe tile and slate ventilators under various air flow conditions. This means that Manthorpe can provide accurate data designers of mechanical extraction systems.

In summary, excess moisture can wreak havoc on a building’s structure and create an environment conducive to mould and mildew growth. Manthorpe roof tile ventilators, when part of an effective moisture control system, effectively manage moisture and prevent harmful condensation. But more than that, Manthorpe’s commitment to external testing, as well as their own extensive design and research programmes, means that specifiers and installers can count on their products to do exactly what they are designed and built for.