When BS 8612 published, the UK roofing industry finally got a British Standard for its dry fix roofing products. Prior to this, dry fix products had been used in the UK for over 40 years, but their design, manufacture and installation had been largely unregulated.

There are many advantages to dry fix, such as being essentially maintenance-free. No matter how well mortar is laid it will eventually succumb to the elements, sooner if it rains or there is a frost before it fully sets. By contrast, as soon as a dry fix system is installed it is ready to face the elements and can cope with settlement of a building by allowing for movement in the surrounding materials.

Requirements of dry verge

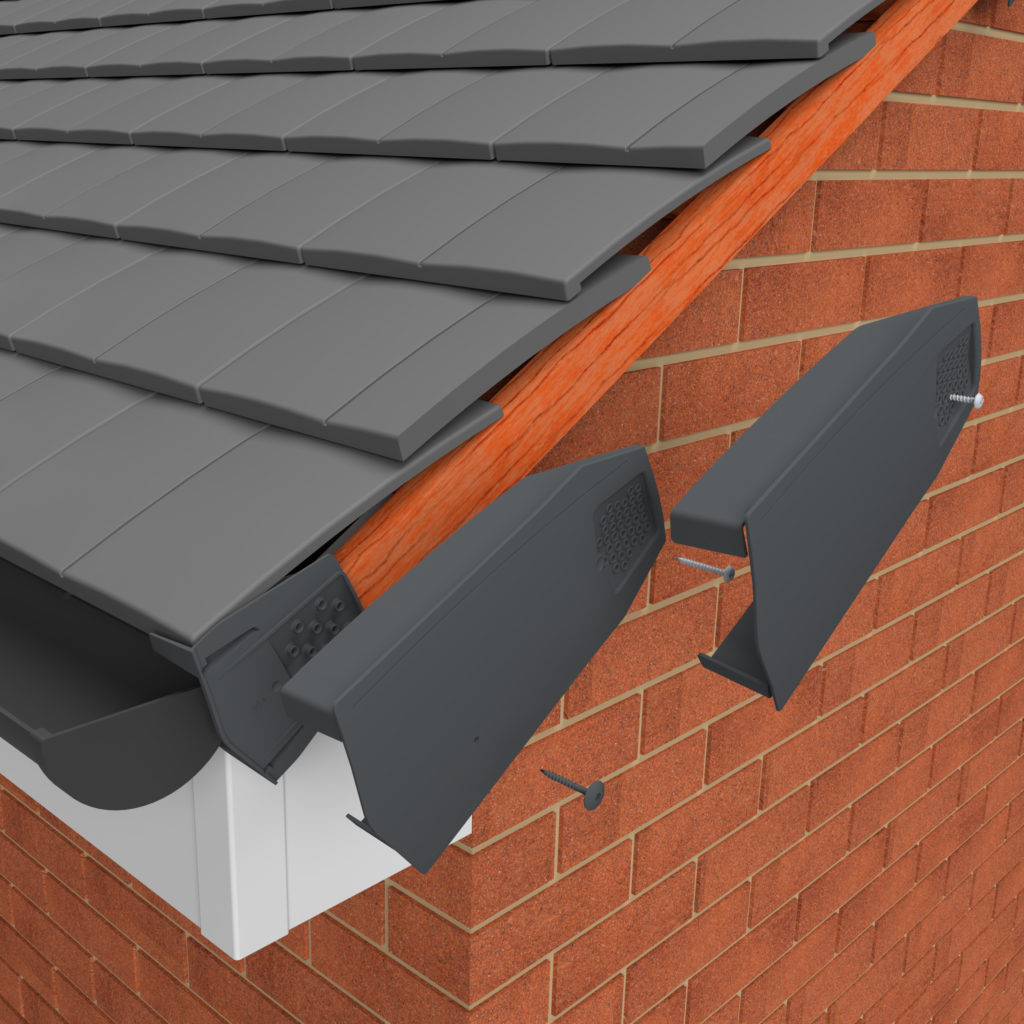

BS 8612 sets out specific requirements for dry verge systems, such as providing methods for uplift testing to ensure they resist predicted wind loads and act as a secondary fixing for the roof covering.

For verge systems to be compliant, they must also prevent rainwater from draining directly onto the gable wall which can lead to staining and mould growth.

Manthorpe expertise

Manthorpe Building Products specialises in dry fix roofing, developing innovative solutions for the construction industry for over 35 years and having invested heavily in new technologies to continue to manufacture virtually all its products in-house to the highest quality. All Manthorpe dry verge products have been independently tested at the Building Research Establishment (BRE) to ensure they fully comply with and, in many cases, go beyond the requirements of the relevant British Standards.

Dry verge products

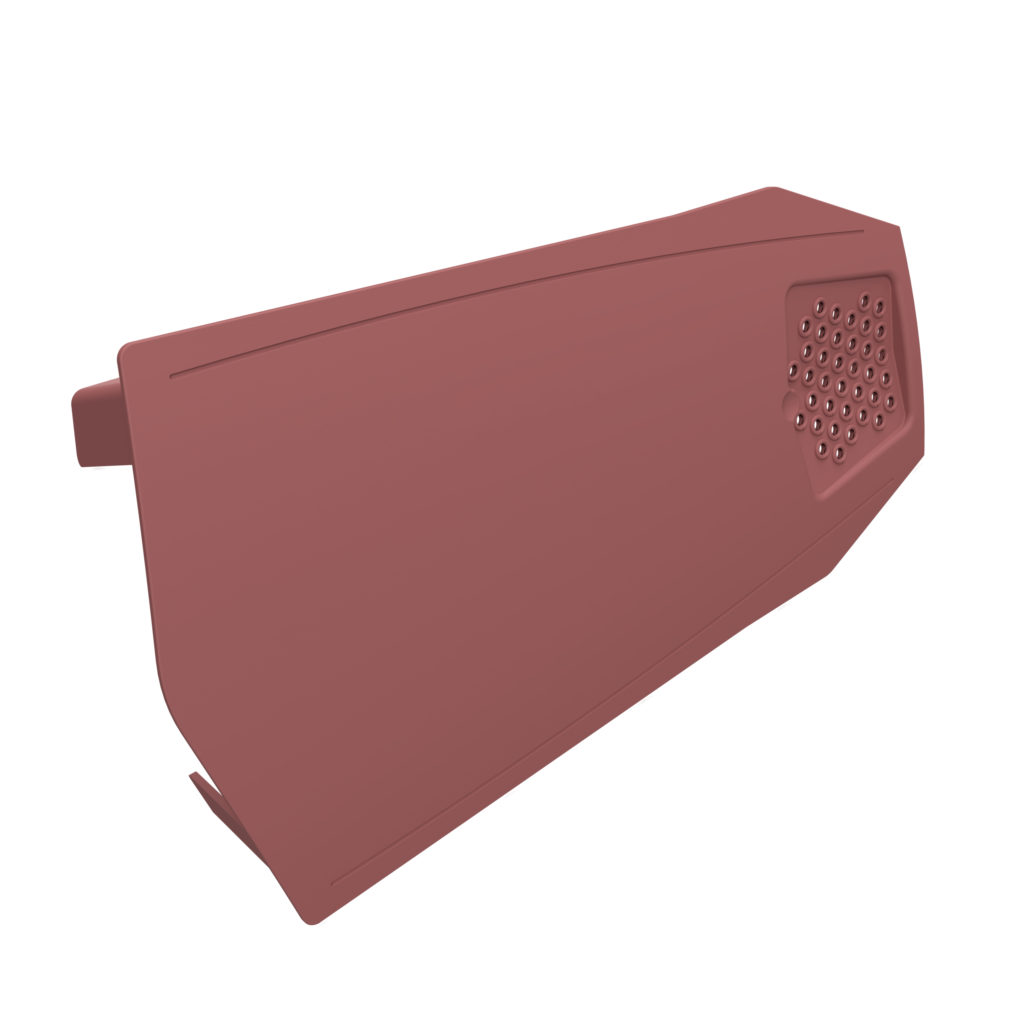

Manthorpe offers several systems in its SmartVerge® range, the Linear System provides a secure mechanical fixing solution for many types of roof coverings requiring a straight, continuous finish: including Fibre Cement and Natural Slates. For a stepped appearance to the verge, the SmartVerge Handed and Ambidextrous systems provide an attractive finish to roofs fitted with interlocking tiles of various size formats, capping one per tile course. The ambidextrous system allows the units to be used on either side of the verge, making it ideal for roofers and stockists wishing to minimise their stock holdings.

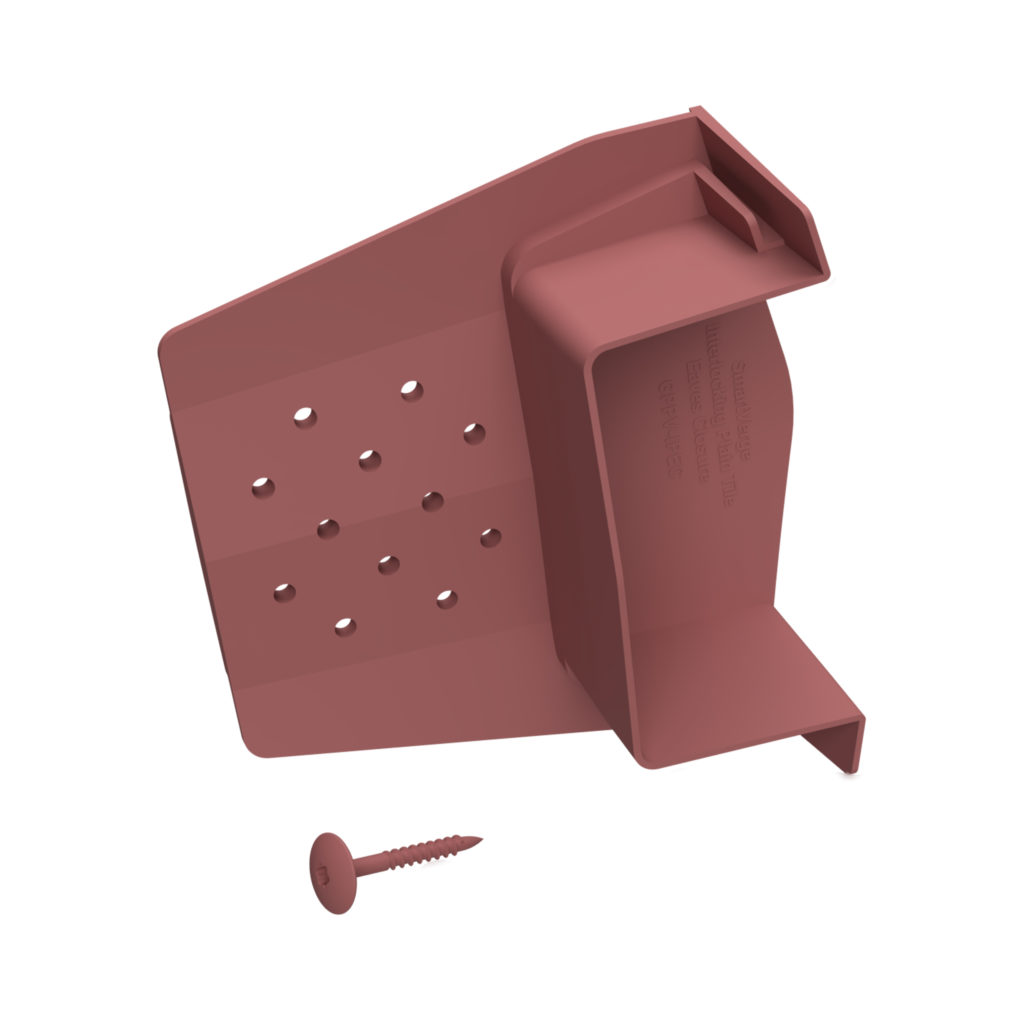

The new SmartVerge Interlocking Plain Tile Verge system includes the ambidextrous design and is manufactured from UV stabilised polypropylene in a range of colours to complement any roof finish. The unique split plate fixing of the verge units means that the upper flange always lays perfectly flat on the roof tile, eliminating any potential tile ‘kick up’ in the tile course above and improving the rate of water runoff from the verge and away from the wall.

For all Manthorpe systems, angled or round end caps are available to protect the end of the ridge and eaves closures secure the first verge unit while preventing access for birds and large insects.

Further information

For further information please visit www.manthorpebp.co.uk or contact our sales and technical support advisors on 01773 303 000 or email us at mbp.care@manthorpebp.co.uk.